HMT MACHINE TOOLS LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HMT MACHINE TOOLS LTD

Sheetfed Offset Printing Machine Single Color

Salient Features :

» Centralised controls: All controls are located ideally on a single console with push button convenience

» Printing Unit: Double blankets for excellent dot reproduction. Non bearer contact design allows flexibility in packing thickness

» Most reliable and maintenance-free pressure vacuum pump for efficiency and reliability of feeding a variety of paper stock, ranging from thin papers of 0.05 mm to thick boards of 0.6 mm

» Electricals: Specially designed electrical components and technologically reliable controls for continuous speed regulation and the best possible electrical efficiency

» Smooth infeed: Eccentric drive for swing grippers aids smooth sheet infeed with minimum vibration

» Crawl speed for faster make ready

» SOM 125B with additional features like

» Bearer contact cylinders for better dot reproduction

» Antifriction bearings for cylinders for better print quality

» Hard chrome plated cylinders for corrosion resistance and durability

» Modified tape roller drive for perfect registration at higher speeds

Heetfed Offset Printing Machine Two Color

Salient Features :

» PLC based Photocell for 'no sheet','cross sheet' and 'overshoot' detection

» Centralised automatic lubrication pump with timer and lubrication reminder alarm

» Lateral and circumferential register adjustments for plate cylinders while the press is running

» Highly reliable pressure vacuum pump

» Motorised feeder pile hoist with pre-piling facility

» Positive and smooth sheet infeed through eccentric swing gripper drive

» Crawl speed for faster make ready

» On-line numbering attachment for both MICR and conventional is available at option

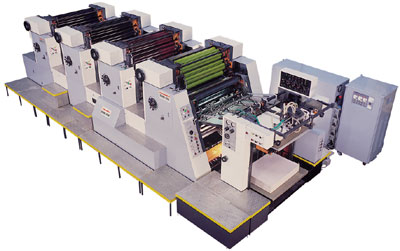

Sheedfed Offset Printing Machine Four Colour

Salient Features :

» Precision ground hard chrome plated cylinder

» 18 Roller inking system with 3 forme rollers

» Double Blankets for excellent dot reproduction

» Eccentric Swing Gripper for smooth sheet in feed

» Programmable logic control for high reliability of the electronic controls

» Motorised dampening fountain roller with stepless speed control and provision for surge control

» Lateral & circumferential register adjustment for the plate cylinder while the machine is running

» Triple size Transfer Drum for better accessibility

» High pile delivery and IR drying at option

» On-line numbering attachment is available at option

» Pneumatic controls

» SOM 425C with continuous film Alcohol dampening system with advantages like

» Instantaneous Ink-water balance

» Less ink consumption and better gloss

» Less moisture - reduction in paper distortion / expansion, thus improving multicolour registration accuracy

» Reduction in make ready time

» Sheet decurler and air brush for image fit as optional

Sheetfed Offset Printing Machine Five Colour

Salient Features :

» Prints 1 + 4 colours retroverso

» Ergonomically designed for ease of operation

» Diagnostic fault display at feeder

» Reliable suction head handles effectively a wide variety of paper stocks from 0.05mm to board of 0.7mm thickness

» Good blending of ink and optimum transfer to the plate for high quality results

» Quick ink/water balance and thin film dampening results in good print quality

» Pin register system and on-line register controls for quick settings

» Anti-marking sheets on transfer cylinders and delivery drums

» High pile delivery with motorized pile hoist and anti-set off powder spray

Programmable Guillotines

Salient Features :

» One of the fastest Guillotines in the world with a mechanical cutting speed of 47 cuts per minute

» The only Guillotine to use a pendulum action on the knife carriage bar which guarantees minimal absorption of energy by working parts resulting in reduced wear and easy accessibility for maintenance of the knife carriage and related functions

» The hydraulic unit is dedicated to maintaining clamp height eliminating the need for counteracting springs

» CNC controlled closed loop mechanism for accurate positioning of back-gauge eliminating the need of the electromagnetic brake mounted on the ball screw axis

» The front face of the clamp has a protective insert to prevent the blade grazing or interfering with clamp face

» Back-gauge position accuracy to + 0.04 mm

» 99 Program channels. Program execution possible either in semi-automatic or fully automatic modes

» Stainless steel cladding on table for surface protection

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.